Important dates

In December 1962, the year when the whole world breathed a sigh of relief due to the decrease in tension caused by the Cuban missile “Caribbean crisis”, the USSR Council of Ministers adopted a decree on the establishment on the basis of the State Union experimental plant № 300 (then OKB No. 300, today Aircraft Scientific and Technical complex ASTC "Soyuz") a Special Design Bureau of turbo-cooling machines (SKB TCM).

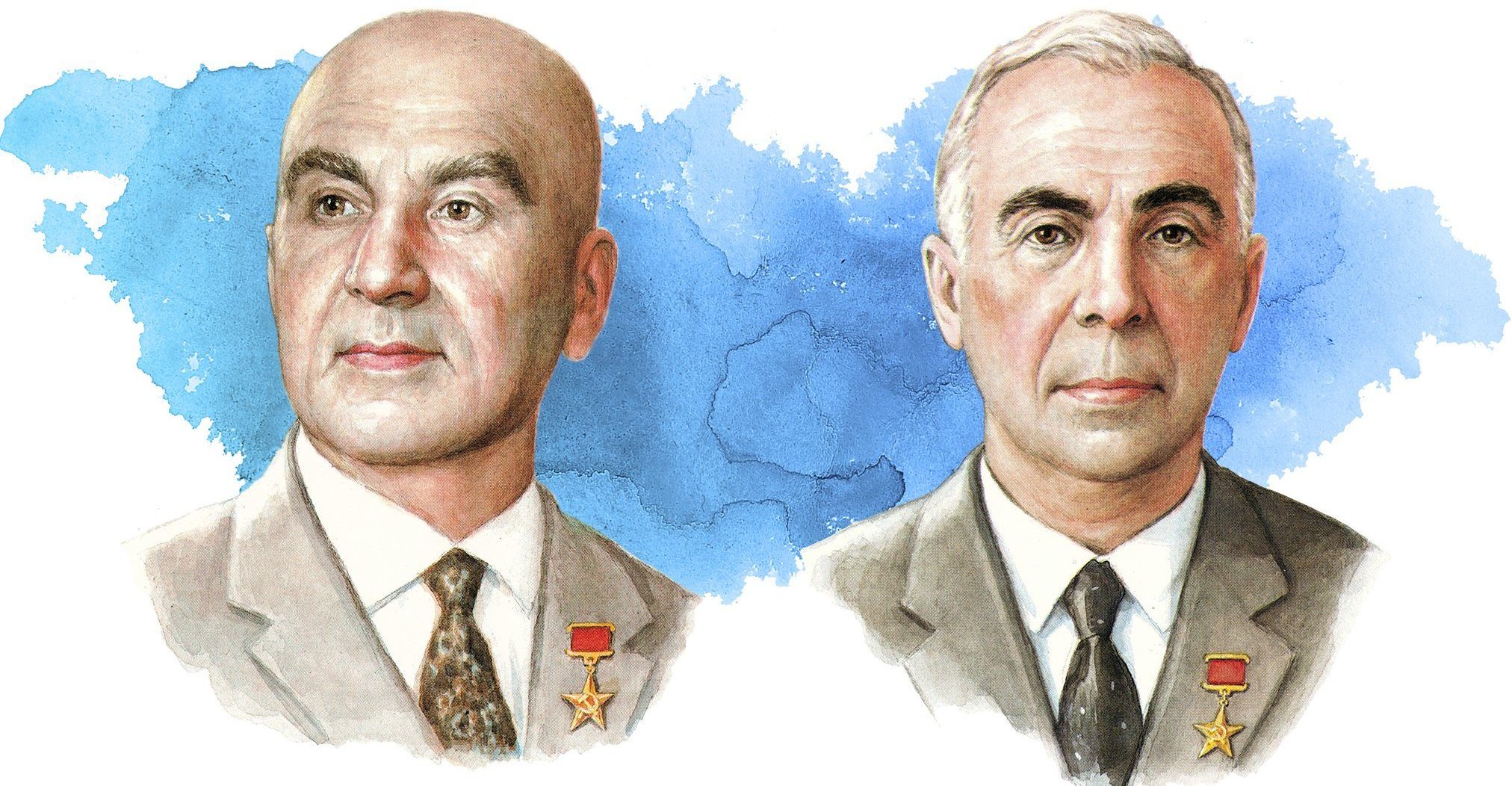

The initiative to establish a branch where the development of air and gas turbo-cooling machines would be carried out was made by two first heads of OKB No. 300, designers of aircraft engines Alexey Mikulin, Sergey Tumansky, and Boris Stechkin — the uncle of Igor Stechkin, the Creator of the famous automatic weapons.

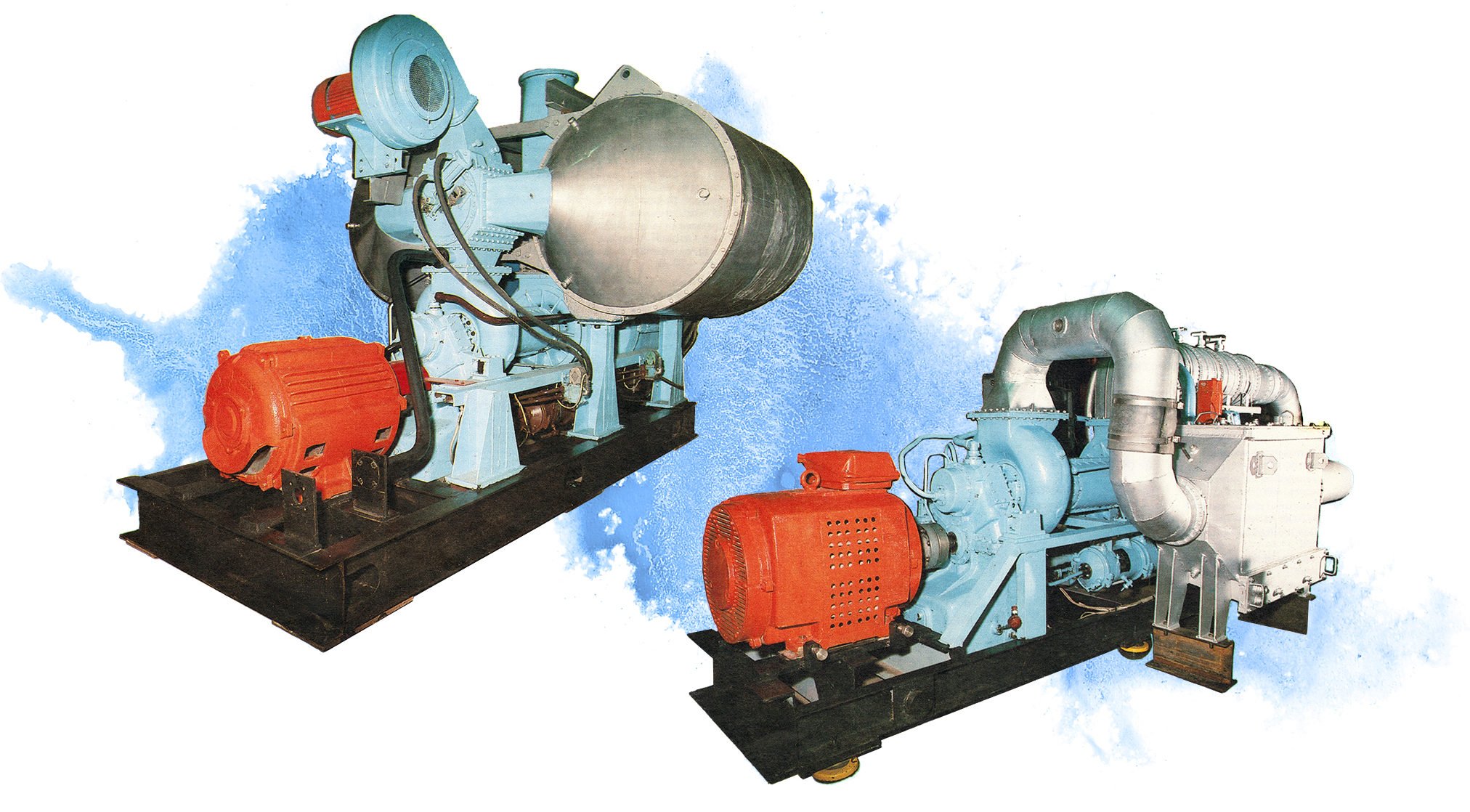

Designers of the Special Bureau design, created and successfully tested the first batches of TCM in the Soviet Union. Subsequently, more than 950 units will be produced for a wide range of applications: from the national economy and healthcare to nuclear power and the military-industrial complex. The main feature – exceptional environmental friendliness, due to the absence of chlorine-containing refrigerants, as well as the possibility of obtaining ultra-low temperatures

A specialized organization for the design and construction of air and gas turbo-cooling machines was created on the basis of the SKB TCM MMZ “Soyuz”. The new division is part of the Main Department of compressor and refrigeration engineering under the Ministry of Chemical and Petroleum Engineering of the Soviet Union.

Minkhimneftemash of the USSR appoints SKB TCM as the head organization for upgrading units for pumping natural gas through its main pipelines (GPA-Ts-6,3) and a range of equipment with increased service life and reliability.

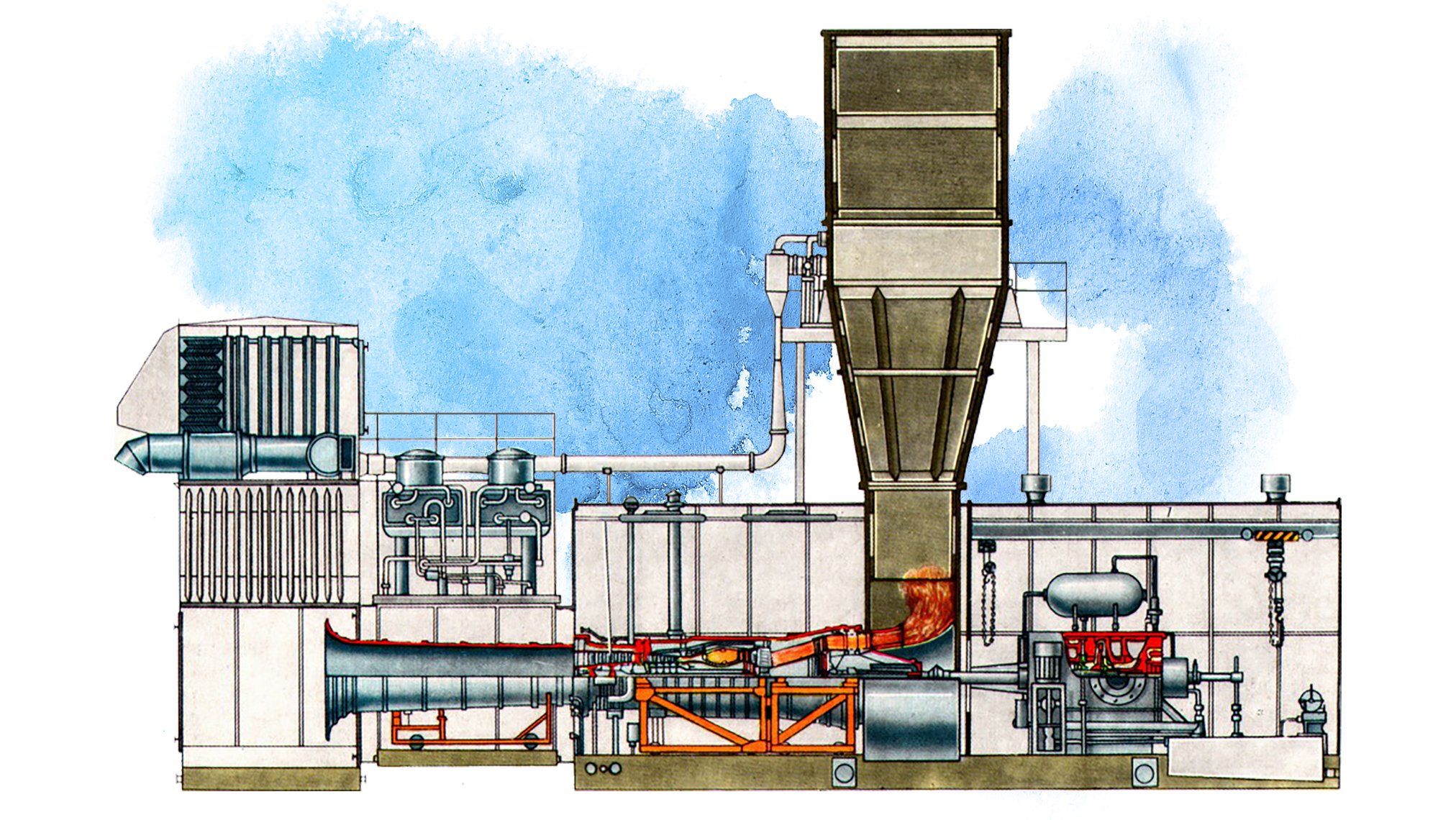

As the parent organization, a Specialized Design Bureau started to create a new generation of gas pumping unit - the GPA-Ts-16, whose mass production began in 1980

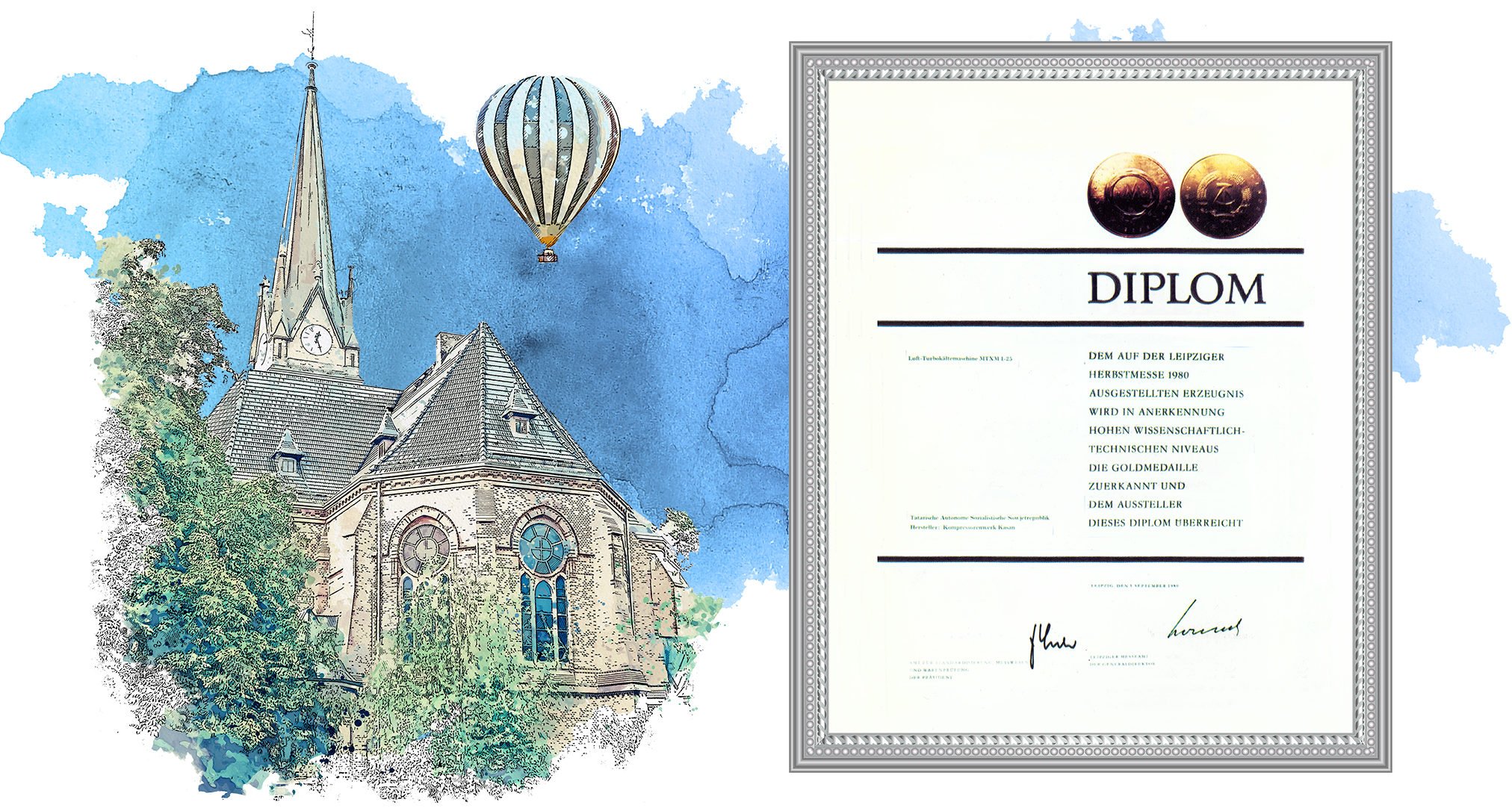

The TM1-25 machine is exhibited at the international exhibition in Leipzig, where it is highly evaluated by experts and awarded a Gold medal and a 1st degree diploma. During this period, the design Bureau in Russia continues actively working on the creation and production of turboexpander units (TDA). Equipment for natural gas separation at low temperature is used for the production of "blue fuel" at the Mashevskoye gas condensate field in the Ukrainian SSR.

Following the development of a new direction of activity — automation and microprocessor technology — SKB changes its name to Special Design Bureau for Automation, microprocessor and turbo-cooling Technology. After conversion experts of SDBA developed a turboexpander with active magnetic suspension. The prototype unit was delivered to “Yamburggazdobycha”.

Work on the TDA for ethane liquefaction, which is being equipped with the Orenburg helium plant, has been completed. Turbo-cooling machines are exported to Vietnam and the United States for companies that recycle tires.

During this period, SKTBA was renamed as the Special Design Bureau "Turbokholod" by the order of the Ministry of Industry, and was transformed into AOOT in 1993. TDA with active magnetic suspension is equipped with a complex gas processing Unit at the Shurtan field in Uzbekistan, and operation of a turbo-cooling machine begins at the airport in Tashkent.

Start of joint activity with the world's leading manufacturer of bearings, lubrication systems and mechatronics — the French company SKF. The result of joint work was the creation of a fundamentally new ADKG-10 unit with active magnetic suspension SKF S2M in 2002. In the same year JSC "Turbokholod" becomes a part of "Mercury" Group of Companies.

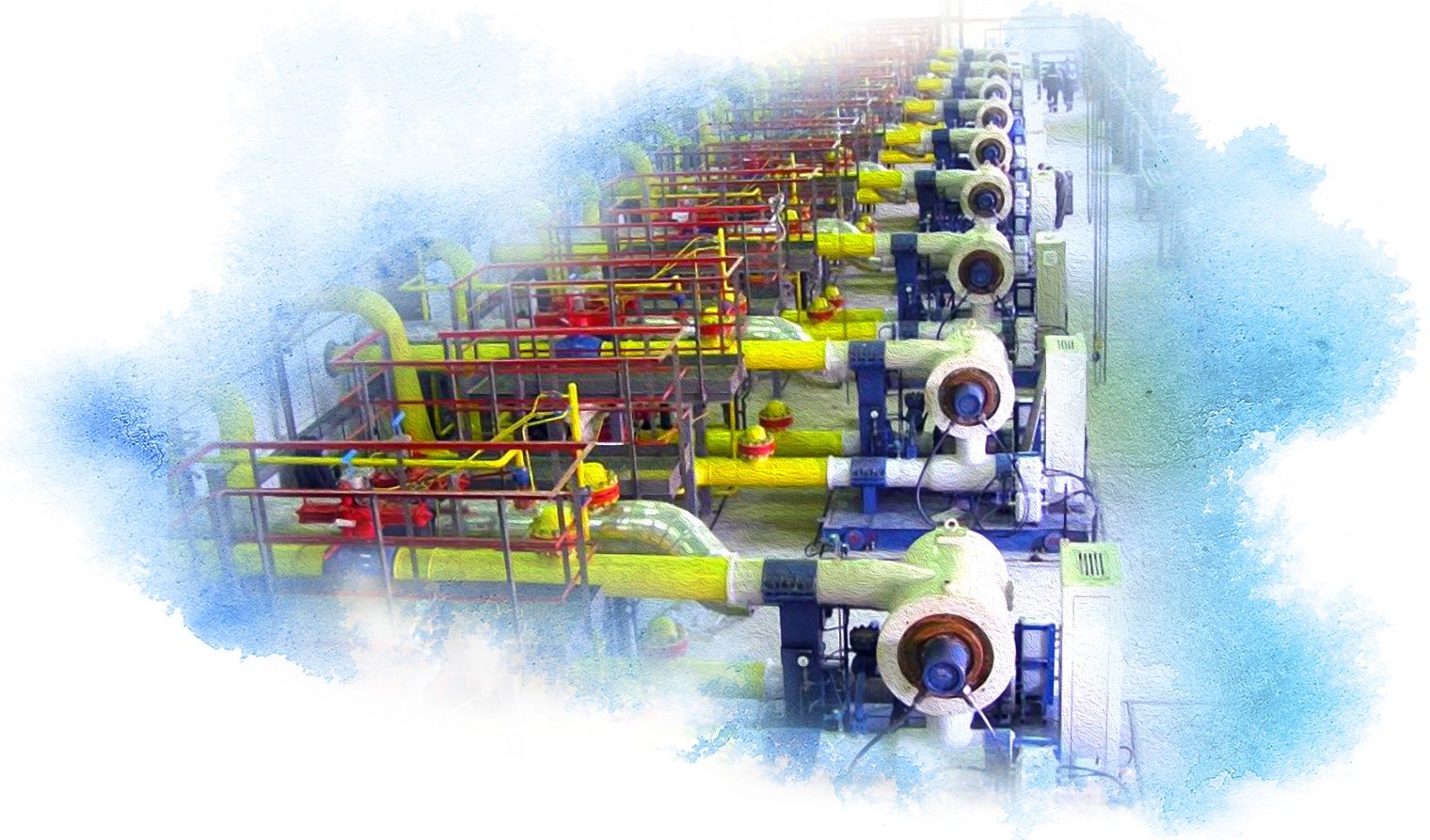

“Turbokholod” fully meets the demand of Russian mining companies for TDA for low-temperature gas treatment at the head stations and units that cool the gas before transportation in the Far North and permafrost areas.

The beginning of the design of the ADKG-20-TDA with a vertical shell connector and increased productivity. During the period of 2008-2012, a total of 89 ADCG-10 units were delivered to the country's key industries.

Start of production of ADKG-20. From 2012 to 2016, 30 units will be delivered, and in total for 2013-2020, the industry will receive 54 turboexpander units adapted to work with gas characterized by a high content of vapor-liquid phase.

The development of complex resource-saving solutions based on a turboexpander unit, including for generating clean electricity, is initiated. The company continues to actively develop in all areas: design, technology, and corporate. Production is being restructured and optimized, a Competence Center is being created, and additive technologies are being introduced.